FishFarmFeeder presented at Aquafuture Spain its new immersion vaccinator for hatcheries.

Dip or immersion vaccination has become a widely spread method to induce protection against infectious disease of fish fingerlings, in particular for all sizes below the minimum required for correct vaccine injection – below 10g. In big hatcheries, this first vaccination process involves handling big amounts of fish being a labor-intensive task.

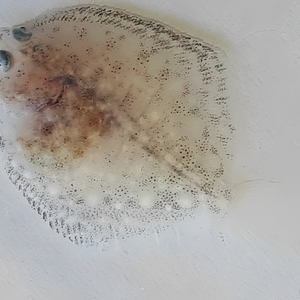

FishFarmFeeder has developed an industrial alternative with a new immersion vaccinator. Fish are delivered to the machine preferably by a fish pump. A dewatering compartment working on a standard draining time allows for fish to fall into the following compartment where 50 liters of vaccine solution stands. Fish are then dipped during the required time according to the vaccine specifications and are automatically scooped out with an efficient draining stage leaving the vaccine solution in place.

The vaccinator reduces the vaccination time by a factor 4 to 5. Only one farmer is required to run the process, mostly to only control that it runs smoothly, while the traditional team often leads to 4-5 people. The dip time can be adapted to any farm particularities, dose time and oxygen concentrations are best controlled and fish stress is reduced.

“We started this project under the request of two fish farms, Fermes Marines du Soleil (Aqualande Group) and ABSA (Cooke/Culmarex Group). Together, we have been developing and validating the vaccinator that has now been running for 18 consecutive months in these two farms without any issues,” Didier Leclercq, aquaculture expert and partner of FishFarmFeeder, told Hatchery Feed & Management. “We have two salmon hatcheries using the vaccinator in Scotland. These farms are run by only a few people so they can now do the process without hiring external staff for the vaccination season.”

“This is an automation of routine-based duties in a hatchery such as vaccination, done in a clean and industrial way as FishFarmFeeder does all its automation,” Leclercq concluded.