European seabass (Dicentrarchus labrax) and gilthead seabream (Sparus aurata) represent around 15% of total European production. In 2021, 255,019 tons and 583,124 juveniles of seabass and 236,632 tons and 698,547 juveniles of seabream were produced in Europe (FEAP, 2023).

The Mediterranean region serves as a significant hub for seabass and seabream farming but shows variations in farming practices, water quality and environmental conditions depending on where a hatchery is located within the region. “One of the biggest differences we see in Mediterranean hatcheries is the use of technology. Turkey and many European countries, such as Spain, Italy and Portugal, are adopting more advanced technology to manage feeds and improve daily operations and production within the hatchery. These countries are also implementing more technology as the cost of labor increases and hatcheries grow,” said Yoav Rosen, global marketing director, Aquaculture, ADM Animal Nutrition.

Rearing conditions are also different. “Western Mediterranean hatcheries tend to reach higher production intensification probably due to operational costs and land availability. The location of the majority of the grow-out farms is offshore in Western Mediterranean, where it becomes complicated to handle fish. This has led to the proliferation of land-based pre-ongrowing units where higher final weights are reached and full grading and vaccination programs can be implemented,” BioMar hatchery team explained.

“In Spain and other Western Mediterranean countries, the increasing trend is to keep juveniles longer in land pre-ongrowing facilities until 16-20g. In Greece and Turkey, juveniles are released to the sea at 2-4g,” said Claudia Maira, senior scientist, VMRD Aquatic Health, Pharmaq AS and Roberto Guijarro, lead of South Europe Pharmaq BU.

These two different production strategies may have consequences for fish health management and fish vaccination. “The longer maintenance of the fish in tanks on land gives the possibility to complete the vaccination regime against the most severe diseases in seabass and seabream before transfers to cages in the sea. By using in-land pre-growing units, the fish will be better protected to be transferred to an environment of high infectious pressure. The downsides of this production system are the higher production costs, especially due to feeding, labor, oxygen and the associated logistic costs,” Maira and Guijarro explained. “However, smaller fish size directly released to sea cages means weaker immune status not only due to their natural immune immaturity but also to having been vaccinated only once by immersion, with shorter and narrower diseases protection, and thus higher susceptibility to infectious diseases. In exchange, this system brings more economic and cheaper juveniles, and lower logistic costs for transportation to the sea.”

Genetics

Currently, most of the commercial seabream and seabass hatcheries rely on spontaneous mass spawning for their production purposes. “Mass spawning systems use random mating which results in a high variance in family size and a high number of non-contributing breeders, especially males. Despite this being an effective and simple way to avoid high levels of inbreeding, the relative contribution of each individual is unknown,” said Panagiotis Kokkinias, breeding scientist at the Center for Aquaculture Technologies.

“Modern mass-selection programs do not utilize one-to-one controlled spawning, and the parentage can therefore not be traced in early life such as in a family-based program. However, utilizing modern genomic tools, such as low-and-medium density SNP-panel genotyping, we can assign the exact parentage of each candidate based on the genotypes of parents and offspring, and thus reconstruct their pedigree for highly accurate mating schemes. Utilizing such tools, we can achieve tight control of inbreeding and genetic diversity in highly cost-effective fully integrated mass-selection systems designed to achieve significant genetic improvement in central phenotypic traits,” said Adrian Antonsen, applied genetics consultant at Benchmark Genetics.

“The use of genotyping data from the breeders allows to manage the family structure and control the inbreeding and the genetic variation of the broodstock population. The implementation of genomic selection to the breeding value of candidates based on their genotype can be used to predict, with high accuracy, complex polygenic traits with high economic value. As such, genomic selection can be used to increase the rate of genetic gain but also to retain the genetic diversity and minimize the inbreeding in a broodstock population,” said Kokkinias.

Genetic selection is gaining more and more interest from producers, especially in big integrated groups. “Genotyping to manage the inbreeding levels in mass mating species is increasingly common. Inbreeding can lead to low vitality and poor resilience in farmed animals, and mass mating in species such as seabream and seabass is no exception. The adoption of genotyping in the management of family structure has resulted in greater control over inbreeding in the past decade than was possible in the past. Using SNP genotyping the parentage of each fish in the program can be determined, and the extent of inbreeding can be measured using analysis of the genetic variation present in each individual. Individuals with closely related parents and high levels of inbreeding can then be excluded from the next generation,” Alan Tinch, vice president of genetics at the Center for Aquaculture Technologies.

How about traits? “The most demanded traits by farmers in the breeding programs often revolve around improving production efficiency, fish quality and animal welfare, such as fast growth, robustness and disease resistance, fillet yield and quality, feed efficiency and environmental adaptation to parameters such as temperature and salinity,” said Antonsen.

“Traits like feed efficiency, which requires accurate individual phenotypic records, are very difficult to measure in commercial rearing environments such as cages or tanks. A recent study has shown that individual feed efficiency is heritable and highly polygenic in seabream. In experimental facilities, the most efficient individuals were also more efficient in groups, and it would be very interesting to repeat this experiment in a commercial rearing environment,” Kokkinias said.

“Avoidance of deformities, which can reach a high incidence as in many marine species, has also been a trait of interest. Also, disease resistance is a key trait. Breeding programs should target to deliver strains that improve the cost of production by increasing the value of the end product and reducing the losses from disease challenges,” said Antonsen.

“Genome editing (GE) for improved fillet yield of seabream is already used in commercial RAS production in Japan. Production in RAS prevents the escape of the GE fish. GE is not considered GMO because no new DNA is introduced, and genetic changes are indistinguishable from natural mutations. We have developed GE to make sterile production fish. Combining GE for sterility and production traits such as fillet yield in seabream and seabass will result in a major boost in performance,” Tinch said.

Broodstock feeds

The broodstock is the heart of the aqua business and strong beginnings at the hatchery level rely on complete and precise broodstock feed. “Broodstock feeds play a critical role in obtaining high-quality fry from hatchery to market. The early life stages of seabass and seabream are highly dependent on consistent feeding strategies and quality feed to ensure growth, performance, survivability and profitability to the farmer,” Rosen said.

“The investments in breeding programs are also pushing hatcheries to pay more attention to the nutrition of their genetically selected broodstock not only from the nutritional point of view but also biosecurity, which is increased when you stop giving trash fish,” said Mario Hoffmann, Jessica Teske and Geert Rombaut from INVE Aquaculture.

“Aqua farmers understand that providing high-quality feed impacts both the fish they’re farming and their bottom line. For the fish themselves, the nutritional status of the broodstock directly affects the quality of the offspring they produce, and high-quality feeds are important for reproductive performance, egg quality and fecundity, larval development and resilience,” Rosen said.

“The initial development of the marine larvae is critically dependent on the nutritional quality of the eggs. Before opening their mouth, the very young larvae go through a huge development and transformative phase only relying on their yolk sack reserves. The characterization of the yolk sack is intrinsically dependent on what and how the broodstock is fed and conditioned. Assuring a biosecure, nutritionally adequate, balanced, health-promoting and stable broodstock feed is key for the initial development of the larvae. This is the foundation for quality larvae and consequently fry and grow-out fish,” BioMar hatchery team said.

Live feeds

Gilthead seabream relies on live feeds for newly hatched larvae and Mediterranean hatcheries have been fine-tuning their live feed procedures to increase larval quality. There have been key developments that allowed reliable and standardized live feed production. “Magnetic Artemia cysts have significantly increased the efficacy and safety of live feed production. Its implementation is widespread throughout the market, although the old technology still has a presence due to the availability of lower-cost non-magnetic cysts. Rotifer husbandry and continuous and semicontinuous rotifer production methodologies have simplified production processes and increased reliability with enrichment as a key step,” BioMar hatchery team said.

“In the realm of aquaculture feed management, the introduction of magnetic technology has brought about a groundbreaking advancement. This innovative technology is applied to Artemia cysts, providing hatcheries with a simplified and efficient method to recover live feed. The technology capitalizes on the principles of magnetism to streamline the recovery of live feed in hatcheries. The Artemia cysts are treated with a unique magnetic coating, rendering them responsive to magnetic fields. This allows for easy separation and collection of the cysts. By harnessing the power of magnetism in combination with specifically designed tools to hatch these cysts, hatcheries streamlined their operations, simplified the recovery process, enhanced the quality of live feed, and contributed to the sustainable growth of the aquaculture industry,” stated INVE hatchery and Artemia team.

Credits: INVE Aquaculture

“Enrichment techniques are common practice within hatcheries, such as feeding specific microalgae or other supplements and nutrients to increase the availability of essential fatty acids, vitamins and minerals, ensuring that the rotifer, Artemia and other live feeds deliver a well-balanced diet to the seabream larvae,” said Rosen.

“During the past ten years, live feed enrichments have evolved focused on simplicity, stability and predictability, giving as a result more friendly to use products, shorter enrichments times and, at the same time, more predictable and consistent outcomes. The composition of the enrichments, microalgae quality and species play an important role in determining the microbial communities associated with the larval stages. Their specific formulations provide different prebiotic effects, affecting the abundance of Vibrio species, either pathogenic or antagonist, in larval culture and can have a modulatory effect on larval resistance to certain diseases. Moreover, the different antimicrobial activity of the different microalgae species can result in higher survival rates and increased growth,” said Julio Docando, business & innovation development director, PTAqua.

Microalgae also play an important role in rotifer enrichment. “Many hatcheries culture or carefully select different strains and species of microalgae for the live feed, which provide the necessary fatty acids and nutrients larvae need in life feeds,” Rosen said.

“Many companies have moved on the algae production from in-house cultures to external supplies and the same seems to happen for the other live feed organisms, outsourcing and focusing on more core aspects of the operations,” said Docando.

“Good quality microalgae pastes (refrigerated or frozen) and freeze-dried products have contributed to simplifying processes with good results in many hatcheries. There are still hatcheries that produce their own microalgae, most often due to the unavailability of off-the-shelf solution for some algal species (namely Isochrysis sp.) and to better results with in-house produced algae,” BioMar hatchery team said.

New live feeds, such as copepods and barnacles, have recently entered the hatchery market. “Its adoption is still in its early phase. It depends on the level of acceptance and modernization of the farm, but also the available resources for research. Though, tangible benefits gradually will persuade producers that need necessarily to produce differently to escape the vicious cycle of strangling for financial sustainability,” said Antonio Coli, global sales director, Planktonic.

Some of these new live feeds, such as Acartia tonsa, are well-known in the scientific community with proven positive impacts in fish hatcheries but it was only in recent years when the commercial and industrial production was accomplished. In the case of copepods, “it took a lot of effort to create the optimal environment for keeping them at resting mode. Their commercialization as a live feed gave the fish market a chance to develop new feeding regimes. A lot of commercial trials have given very good results with better growth rates, better survival, and better robustness to be the most efficient. Furthermore, fewer deformities and better food conversion rates constitute the major outcomes as starter food,” said Nikos Mitrizakis, customer service representative at CFeed.

“Tests have been done with very interesting results, although current introduction in standard practice is still reduced in all fully established species (seabass, seabream, meagre and flatfish) especially compared to species where the larval culture is yet under early development and where adoption rates are larger. In these species, novel live feeds can help overcome survival bottlenecks in early stages and can make all the difference for the success of a project,” BioMar said.

“A combination of an ultra-high nutritional value starter feed and an easy-to-use dry feed for the continuation could be the future for the Mediterranean hatcheries,” said Mitrizakis.

Being very labor-intensive, live feed production represents around 25% of the hatchery costs. “Costs can be reduced through further standardization of processes and simplification of protocols. New digitalized tools, such as live feed counters, feeding automation, and precision feeding, will increase accuracy and help decrease costs. The development of early dry feeds can also reduce the dependency on live feeds,” said Hoffmann, Teske and Rombaut.

A way to reduce these costs is by replacing live feeds with dry feeds. “Today, it is not possible without a relevant impact on productivity, especially morphological conformity, and even if it was possible, the long-term effect on performances and robustness in grow-out stages should also be assessed. Other ways in which live feed costs can be reduced are the use of novel microdiets and implementing high production standards (zootechnics, feeds, general practice, etc.),” BioMar said.

“Artemia replacement remains the great challenge in the industry. Different efforts have been done in this direction, but there is still no definitive solution without impacting larval yield in terms of survival, malformations, quality, growth, etc., and the process requires a hard commitment from technicians who are usually under high production pressure,” Docando said.

Credits: INVE Aquaculture

Dry feeds

“Over the past 30 years, we’ve seen significant improvements in hatchery production, specifically in the quality of feed, how the feed is developed, and the technology used in feeding production and development. These changes have reduced the need for using rotifers and Artemia as live feed by up to 50% or more, in some cases,” Rosen said.

This reduction was thanks to dry feeds. “New advancements and improvements include product technology enabling microencapsulation and particle size optimization, improved and balanced nutritional compositions and a reduction on the dependency of live feeds,” Rosen said. “Microencapsulation technologies are helping enhance hatchery operations and co-feeding strategies leading to better survival rates, growth performance and overall health in fish larvae. At the same time, cold micro-extrusion technology is important to maintain the integrity and stability of the feed when submerged in water and to prevent the denaturation of temperature-sensitive ingredients during the feed production process. For nursery feed, cold extrusion is becoming more prevalent.”

“Larval and weaning feeds are in a process of continuous development. The different processing technologies applied to fish feed can give a better result in terms of physical characteristics, digestibility, palatability, water behavior and stability. Hatchery managers can choose from a wide range of products, depending on what best suits their species, feeding techniques, facilities, processes, sensitivities and experience,” Docando said.

“Characteristics of current top-end feed could be summarized in the selection and stable supply of the highest quality raw materials, and manufacturing technologies designed for optimal nutrient preservation and digestibility, while at the same time maximizing physical characteristics both of the dry product and especially once the product is in the water, exhaustive quality control on both nutritional and physical characteristics, and good understanding from the manufacturer of the use of the product and strong collaboration and support to the end-user (the hatcheries),” BioMar hatchery team said.

Dry feed introduction from the start of exogenous feeding in marine fish larvae has always represented a major challenge. “It is extremely complex to produce a diet that can be ingested and digested correctly at such early stages of larval development,” stated Jessica Teske, scientist nutrition, INVE Aquaculture. “The progress regarding feed technology supported the aquafeed companies to be able to produce diets in smaller sizes that can partially reduce the dependence on live feeds. This is still an ongoing process, and a lot still needs to be done, but such an advance enabled us to introduce diets on open month, which resulted in the more consistent production of fry since we reduced the risk associated with the nutritional variability of live feeds but also keeping the quality and predictability of the fry produced,” stated INVE hatchery team.

“Since 2021, several commercial-scale trials have been performed to validate a feed strategy that enables to reduce the usual daily rotifer quantity by at least 50%,” said INVE hatchery team. “From our experience, we learned that success in applying this feeding strategy starts from using a powerful combination of a few but very important high-quality rotifers (properly cultivated, enriched, and under microbial control) with a diet designed with particular attention to ingredient selection targeting optimal nutrient assimilation and palatability, as well excellent stability of the feed particle avoiding the leaching of nutrients and, thus, guaranteeing the attractiveness of the feed for larvae from the start of exogenous feeding. To ensure optimal results when substituting a critical feed item like rotifers without any compromise on quality and performance implies that nutrition in the following stages is of the highest standard and that the successive formulation supports high survival rates and easy weaning even at high survival rates, guaranteeing that larvae are at least as robust as the ones fed with standard rotifer quantities.”

“Even though these new feed technologies provide much better characteristics of starter feeds, the adoption by producers has not yet reached the level that it should be based on the results. This is due to conservatism and an unwillingness to dedicate the resources to slightly adjust the production systems of these feeds,” Coli said.

There is also still room for improvement in hatchery operations through new technologies and improved management. “Automation and digitalization will add up to the accuracy of processes and results. Accurate enumeration of Artemia and rotifers is a critical step in hatchery management. Traditionally, this process has been time-consuming and prone to human error. However, the introduction of an automated AI-based prototype counting tool will bring big improvements in counting practices in hatcheries. By the use of advanced machine learning algorithms to analyze images of Artemia and rotifers, the quantities will be accurately determined within seconds. It will help operators become more efficient, accurate and fast, resulting in cost savings for the hatcheries and it will de-risk the high-risk hatchery segment,” said INVE hatchery and Artemia team.

“Other improvements may come from an increased understanding of the tank – both live feed tanks and larval tanks – as ecosystems with different factors at play – biotic and abiotic – that will lead to stronger live feed management and especially to microbial management strategies. A lot of work can still be done on feeding management during larval stages, the number of meals, timing, densities of prey, management of the internal embryonic reserves of the larvae, etc.,” BioMar hatchery team said.

Production failures

Production failures are a common issue and sometimes difficult to address in a multifactorial rearing system such as these species’ rearing systems.

“The maturation of the sector and the ‘selective pressure’ of economic performance have come a long way in the reduction of production failures. Nevertheless, the fragility of early larvae, their fast development, the high productivity demand and the fact that numerous factors are still not under our control, make, from time to time, production failures almost unavoidable,” BioMar hatchery team said.

“Classic failures are often related to physicochemical parameters, such as poor dissolved oxygen monitoring, non-calibrated pH probes or cavitating pumps producing gas supersaturation. Not so acute but especially delicate, and where failures tend to have large impacts, are rotifer production and early larval rearing problems, which may seriously compromise full production cycles. Maintaining a stable production of live prey, not only in terms of numbers but also in terms of nutritional quality and biosecurity, is a crucial and often under-looked aspect of larvae production,” BioMar hatchery team said.

“Marine hatchery results have improved quite substantially in recent years. Even though the survival rates have increased, some hatcheries still face problems of deformities which can hinder final output and profitability. Improvements can come from more balanced and standardized nutrition given to larvae through precision feeding, as well as genetic improvement, and solutions that contribute to overall increased biosecurity, etc.,” said Hoffmann, Teske and Rombaut.

There is evidence that certain factors play important roles in skeletal deformities. Recent studies suggest that these deformities may have a genetic origin. “An accurate early phenotypic analysis of each type of deformity could increase the precision in the estimation of the genetic parameters and increase the accuracy of genomic selection. In addition, the effect of the candidate's genetic background related to the inheritance of a deformity is reflected in their egg-laying quality. It’s very important to know the genetic background of each candidate to estimate accurate breeding values and select the most efficient fish among selection candidates,” said Kokkinias.

“Other factors such as hydrodynamics are important in certain cases of haemal lordosis and poor water quality in some cases of operculum deformities. But there are very few certainties about the causes of deformity and very many unknowns. What seems clear is that skeletal deformities are the result of the combination of different factors, some of them with higher weights than others, when this combination of factors goes over a certain threshold deformity happens,” BioMar hatchery team said.

Nutrition, daily husbandry and environmental conditions are other key factors. “The aim is to reduce the ‘deformity pressure’ trying to keep it under the threshold, but there are no guarantees and a lot is yet to be learned, in most cases through multiple and painful trial and error,” BioMar hatchery team said.

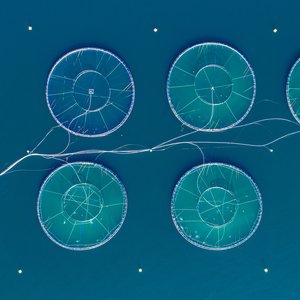

RAS and new management and monitoring tools can also be useful tools to reduce production failures. “Integrating RAS technology and advanced management and monitoring tools in seabass and seabream hatcheries offer improved control over water quality, feeding strategies, disease management and overall production efficiency,” Rosen said.

But how is their implementation in seabass and seabream hatcheries? “RAS systems have a wide presence in hatcheries throughout the Mediterranean, amounting to around 50-60% of the farms and systems. The implementation varies from farm to farm and even inside individual farms, where RAS may be present in some sections, units or phases while others run in traditional flow-through,” BioMar said.

“There is great room for further improvement in RAS. Monitoring tools have been also underexploited in the Mediterranean with serious implications on operating costs (labor costs), risk costs and underperforming,” said Coli.

Disease management

Improvements have been reached in the past few years in both seabass and seabream health, driven by better biosecurity procedures, vaccination tools, feed quality, facilities, and farming practices. “Biosecurity is a major concern in all hatcheries around the Mediterranean industry. From broodstock to juveniles, every farm has developed a biosecurity plan, focused on prevention. From the feed perspective, the role of functional ingredients in these early stages is becoming increasingly relevant. We try to develop deeper knowledge in this area, but the limitations of EU regulations are becoming more stringent,” Docando said.

Despite these improvements, there are still many infectious and parasitic diseases challenging Mediterranean aquaculture production. “Infections in seabass caused by Aeromonas veronii, Aeromonas salmonicida and Vibrio harveyi, as well as by new virulent strains of Photobacterium damselae piscicida, are impacting negatively production performance and fish health status. Likewise, Photobacterium damselae piscicida infection pattern in seabream has changed significantly in some countries, affecting fish of 100-200 g or even bigger sizes. The massive adoption of autogenous vaccines use, although being a moderately useful tool, may bring relevant risks to the health status of the farm in case of replacing completely the use of commercial fully documented and licensed vaccines by them,” Guijarro said. “Autogenous formulations for controlling some of these new emerging threats must be an additional tool to commercially licensed vaccines for which efficacy and safety have been proved by exhaustive documentation and also required before every newly produced batch of vaccine is released. Moreover, investments in licensed vaccines technology improvement for seabass and seabream can be compromised by these autogenous vaccine use trends, chasing away the availability of new high-level vaccination tools.”

The approach applied in Atlantic salmon developing disease-resistant or resilient strains is expected to be also applied in seabass and seabream. “Genotyping using panels of genetic markers are used to identify which regions of the genome cause disease resistance or susceptibility. Major genes often called QTL (quantitative trait loci) have been identified and used to select salmon that are resistant to IPN. More often, where disease resistance involves many genes, marker panels are used to breed for disease resistance using genomic selection. The same approaches can be used in seabream and seabass to develop disease-resistant strains,” Tinch said.

“There might be room to work more intensively on more disease-resistant fish strains against, for example, Photobacterium damselae piscicida in both seabass and seabream, or Sparycotile/Microcotile spp. resistant strains in seabream, Vibrio harveyi in seabass, etc., which might be one of the most promising research fields for Mediterranean aquaculture in the upcoming years. Also breeding for resistance against bacteria and viruses that affect fish at early stages of production, before they reach vaccination size, will be beneficial,” concluded Guijarro.

Don't miss the previous articles in this series:

A look at salmon farming: Genetics, disease resistance and RAS

Tilapia farming I: Genetics, diseases and scale challenges

Tilapia farming II: A look at the main producing countries

Shrimp I: Genetics for growth and robustness