Salmon farming is a mature industry with an established value chain and proven technology with 2,719.6 thousand tonnes produced of Atlantic salmon in 2020 (SOFIA, 2022). Hatchery Feed & Management talked with some key suppliers to discuss the current challenges from the hatchery perspective and get a look at the current trends.

Success starts at the hatchery, and high-quality eggs are a major factor in the performance and survival of salmon. “It should be said that these days, there are no real ‘bad eggs’ anymore,” said Bram Geurts, director of sales & marketing and salmonids, Hendrix Genetics.

The use of genomic selection is now routine in most, well-run salmon breeding programs. “This technology gives faster, more accurate improvement in traits such as disease resistance, fillet yield and quality. Genomic selection needs to be applied in a balanced way to ensure that high performance is delivered along with good health and welfare and high quality of the final product for the consumer,” said Alan Tinch, vice president of genetics at the Center for Aquaculture Technologies.

What does the industry demand?

Selecting for growth has dominated selection profiles for generations, but salmon farming is continuously evolving. “Producers are now refining this approach and looking for a more complete profile of efficiencies from fillet yield, improved survival and disease resistance, reproductive output and even FCR,” said Chris Wallard, COO at Xelect.

“There is a trend to use increasingly innovative technologies for automated and accurate recording of traits, such as new imaging and artificial intelligence systems. Year-round and increasingly land-based production of eggs, with the associated biosecurity benefits, is also a trend,” said Andrew Preston, trait development lead at Benchmark Genetics.

Reproductive technologies, such as cryopreservation of milt and the development of diploid sterile fish are also a current major focus. For RAS, the main trait, in addition to fast growth, is flesh quality, mainly defined by pigment and fat content.

“We’re also seeing temperature tolerance becoming a major issue for some producers, due to rising water temperatures globally. Rising temperatures increase stress in the salmon, slowing down growth and also increasing susceptibility to harmful pathogens that are more abundant in warmer waters. Preliminary trials for identifying families with better resilience to high temperatures are underway, particularly in Oceania,” Wallard explained.

Another important requirement is resistance to specific diseases that varies by geography. Infectious pancreatic necrosis (IPN) QTL resistance is a near-universal requirement and a case of success, with the sustained reduction in mortalities observed in all major salmon-producing countries.

Resistance to cardiomyopathy syndrome (CMS) is key for European net-pen production, while the same is true for the salmon rickettsial syndrome (SRS) in Chile. Resistance to sea lice is also important to many net-pen farmers across the globe. “We are observing very significantly improved performance for CMS resistance in net-pen environments using selected vs unselected material for this trait. We have observed similar realized genetic improvement for resistance to pancreas disease, sea lice, and infectious salmon anemia,” Preston explained.

When it comes to disease resistance, cooperation with academia has resulted in several projects looking for solutions. “Most resistance to pathogens remain multi loci, where gradual resistance or robustness is built into the breeding programs. The studies that Hendrix Genetics did together with the Roslin Institute on the NAE-1 gene are very promising, as they identified a gene that is known to be a ‘portal’ for the replication of viruses. Individuals, where this gene is defective (or switched off), have seen much larger robustness and resistance. While finding individuals with a natural defect in this gene might be a needle in a haystack, it holds significant potential,” Geurts said.

Credits: Thomas Morel, Benchmark Genetics

Moving to RAS

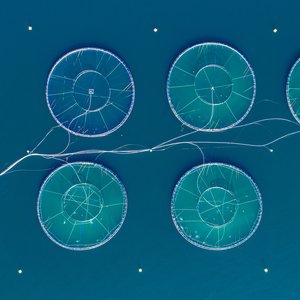

As the industry is setting up more land-based RAS farms, new challenges arise but some others remain the same. “The common challenges haven’t really changed over the years, the main being obtaining a permit. Assuming that’s already been done, financing is always the next biggest hurdle. If you have those conquered then you move on to that next question in terms of farming technology,” said George Nardi, Innovasea vice president of aquaculture services.

And how mature is farming technology? “It’s a little sector dependent – hatchery and smolts vs. grow-out. Companies have been using RAS for decades in hatcheries and smolts. What remains challenging is the grow-out stages from 1 kilogram to a harvest size of 4-5 kilograms. The challenge is doing that at the scale we’re all discussing now – 5,000 tons and larger. There is no precedent, and there is no model, so we will all learn what we don’t know as we do this – and that includes how systems operate, and how feeding and feed formulation have to be modified or adjusted given the system,” Nardi said. “Scale is not linear. Just because you can do something at 250 tons doesn’t mean you can do it at 10,000 tons.”

Feed technology is another pillar to support these systems. “A number of the major feed companies have introduced RAS-specific feeds, which feature fecal binders designed to allow the more efficient solid recovery phase of water treatment in the RAS loop. There are also, now specific sterile salmon feeds which have different nutritional profiles to traditional salmon feeds and are being used successfully in land-based operations,” Preston said.

“In RAS systems, the same particles from uneaten feed and feces remain in the system and can have an effect on the system and, in particular, the filters. Land-based feeds must be designed to have as minimal adverse effect as possible on the system and water quality while encompassing the right nutritional components to guarantee exceptional growth performance, health and welfare of the salmon,” said Fredrik Witte, managing director, Cargill Aqua Nutrition North Sea. “We are using our research and development expertise to develop sustainable feed solutions tailored to our customer's goals, including high biological performance and premium product quality.”

“There is a general expectation that employment of RAS will provide improved control of the farming environment and presence of pathogens and significantly reduce the occurrence of disease. Experience shows that new stressors are introduced in closed systems and it is nearly impossible to maintain a pathogen-free environment. Differences in environment and water chemistry compared to open-water farming may also open up new diseases and health challenges, and the environment and health and disease challenges will likely vary highly between systems. Monitoring the environment and fish health through targeted analysis and diagnostics will therefore be essential for understanding the epidemiology, optimizing biosecurity and developing and employing the right vaccines,” said Marie Egenberg, business unit director salmon Europe and global marketing, at Pharmaq. “Microbiota in the water is expected to play a vital role in affecting fish health and welfare. Pharmaq Analytiq contributes with new and advanced diagnostic tools, and through our new service Next Generation Sequencing, we are confident that we enable the possibilities for accurate and in-depth diagnostics.”

The best way to reduce the impact of disease in aquaculture is prevention, and the first line of defense is fish health and biosecurity. "Today, salmonids are routinely vaccinated against up to nine different bacteria and viruses. While production has grown, the use of antibiotics in Norway has been reduced to nearly zero,” Egenberg said.

Looking ahead, new technology is expected to be developed with an impact on RAS. “RAS is a complicated system that involves biology and chemistry and all of the gains are incremental. What should be expected in the short term is continued incremental progress because even if there is disruptive technology, it’s likely on one aspect of the process, not the entire process. Two areas where we could see some significant developments in the next few years are purging and biofilters,” Nardi said.

New markets and local issues

Several Asian countries have started salmon projects out of the traditional geographies – Norway, Scotland, Canada and Chile. One of these projects is Proximar Seafoods' land-based salmon farm in Japan. “This project has recruited very experienced staff and has taken in multiple batches of salmon eggs from Benchmark Genetics Iceland. It has taken support from technology, genetics and feed providers, which has provided the project access to the wide-ranging expertise in many aquaculture disciplines,” Benchmark said.

“We are thrilled to see interest and success in salmon aquaculture in an array of geographies,” Witte said. “Land-based systems are not without their challenges. As systems, knowledge and technology evolve, we will continue to improve and overcome obstacles. Cargill Aqua Nutrition has a global footprint and with our experience and knowledge, and our willingness to learn, problem-solve and evolve in both land-based and traditional farming, we look forward to supporting new and existing salmon systems around the world.”

Several countries in Europe and North America have introduced restrictions on the transport of live salmonid eggs across national boundaries disrupting models. For example, exchanges of salmon eggs between Norway and Scotland have been disrupted, and many regions in North America are also subject to strict limitations.

“Furthermore, over the last couple of years, we’ve seen first-hand how easily international trade and import routes can be disrupted, whether through geopolitical issues or due to major pandemics. We’ve seen a sharp increase in the number of producers who are looking to de-risk their business model and reduce their reliance on egg supplies that may have to travel thousands of miles. Producers are also recognizing that running their own breeding programs can cost much less than they think, and allow them to develop their own strains that thrive in their own unique production conditions, rather than accepting a compromise,” Wallard said.

“There is a balance between the cost of running breeding programs and the return delivered in improved cost of production. When CAT works with companies – big or small – it looks closely at the appropriate level of technology to be used (i.e. cost) in comparison to the value created as a result of improved performance. Obviously, the value is greater in bigger companies but usually, there is a favorable return on the investment in new genetic technology in all companies. CAT anticipates that with new technology such as genome editing, the return on investment will be large because of faster and more precise improvements. Producers will be willing to invest in this new technology because of the increased return from genetically improved strains,” Tinch said.

The future

The financial climate for aquaculture projects is expected have a strong impact in the short term. “In the past 3-4 years, the cost of entry has gone up for a variety of reasons – from the pandemic and supply chain challenges to global inflation and the war in Ukraine. A lot of projects were put on hold and now companies have come back to find costs have skyrocketed and their budgets have blown up. So some of these projects might not get off the ground or may have to be scaled back in size and scope,” Nardi concluded.