Taste of BC Aquafarms, a wholly-owned subsidiary of Blue Star Foods Corp., completed a preliminary design layout for a new 1,500-ton steelhead farm in British Columbia.

Leaders at Taste of BC Aquafarms worked in conjunction with engineers at PRAqua to design a standardized module that will be used to initially develop up to 1,500 tons of annual production and is ultimately expected to reach up to 21,000 tons of annual production over the next few years. The company is leveraging technological advances in Recirculating Aquaculture Systems (RAS) and nearly ten years of operational experience from its proof-of-concept facility in Nanaimo to incorporate lessons learned and develop a large-scale, state-of-the-art production facility. The Nanaimo facility, which has achieved above target production continuously for nearly two years demonstrating successful proof of concept, is a strong basis for the company’s confidence in the project.

Steve Atkinson, founder of Taste of BC, commented, “we have a proven production system at our current facility that has continuously exceeded our design and production objectives and is delivering consistently repeatable results. With this successful proof-of-concept as our basis, we are moving forward with confidence to develop the first salmon RAS designed from actual production outcomes. Our unique, modular approach will enable us to scale production to meet increasing demand and reduce capacity risk.”

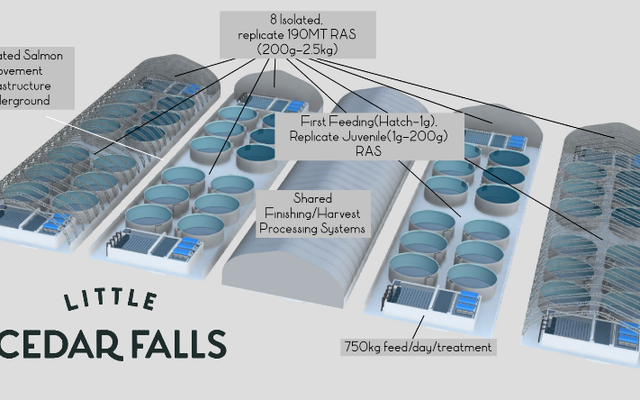

The new RAS modules are each expected to produce 187.5 tons of steelhead annually, with a single farm consisting of eight modules of six tanks each, with two modules per production unit. The production system is designed such that all established and proven operating procedures and protocols are directly transferrable to the new facilities. Taste of BC will continue to use fluidized sand bed technology for biofiltration, and low head and low energy use will also be a hallmark of the new modules. The proposed facilities will also feature on-site, redundant hatcheries, primary processing and waste capture and remediation.

Ben Atkinson, CEO, said, “we have successfully translated our years of operational experience into the design for our new farm and are eager to move to the next milestone. Designing our farms with the ability to scale seamlessly allows us to be more efficient, capture the benefits of known outcomes and leverage our operations to offset the high cost of labor. Importantly, we are also incorporating advancements in RAS technology that have been developed over the last decade since we launched our initial facility.”