Abstract

The successful farming of tiger shrimp (Penaeus monodon) in India is mainly due to the existence of some 300 hatcheries whose capacity to produce 12 000 million postlarvae (PL) annually has provided an assured supply of seed.

However, the sustainability of the sector is still hampered by many problems, foremost among these being a reliance on wild-caught broodstock whose supply is limited both in quantity and in seasonal availability and that are often infected with pathogens.

The current low quality of hatchery produced PL is a major obstacle to achieving sustainable shrimp aquaculture in India and the Asia-Pacific region. The problem arises due to infection with white spot syndrome virus (WSSV) and other pathogens entering the hatcheries via infected broodstock, contaminated intake water or other sources due to poor hatchery management practices, including inadequate biosecurity.

Considering the major contribution of the tiger shrimp to global shrimp production and the economic losses resulting from disease outbreaks, it is essential that the shrimp-farming sector invest in good management practices for the production of healthy and quality seed.

This document reviews the current state of the Indian shrimp hatchery industry and provides detailed guidance and protocols for improving the productivity, health management, biosecurity and sustainability of the sector.

Keywords

Tiger shrimp, Penaeus monodon, India, shrimp aquaculture, biosecurity, sustainable production

Table of contents

1. INTRODUCTION

1.1 Shrimp hatchery development in india

2. MAJOR REQUIREMENTS FOR EFFECTIVE

HATCHERY PRODUCTION

2.1 Infrastructure

2.2 Facility maintenance

2.2.1 Maintenance of machinery

2.2.2 Regular cleaning and disinfection water,

aeration and drainage pipelines

2.2.3 Maintenance of tanks

2.2.4 Maintenance of filters (slow sand, rapid, cartridge, UV/Ozone)

2.3 Inlet water quality and treatment

2.3.1 Quality of intake water and treatment options

2.3.2 Inlet water treatment protocol

2.3.3 Seawater intake

2.3.4 Sedimentation/sand filtration of inlet water

2.3.5 Disinfection of inlet water using chlorine

2.4 Wastewater treatment

2.5 Biosecurity

2.6 Standard operating procedures (Sops)

2.7 Hazard analysis critical control point (HACCP) approach

2.8 Chemical use during the hatchery production process

2.9 Health assessment

2.9.1 Level 1 health assessment techniques

2.9.2 Level 2 health assessment techniques

2.9.3 Level 3 health assessment techniques

3. PRE-SPAWNING PROCEDURES

3.1 Wild broodstock

3.1.1 The broodstock capture fishery

3.1.2 Broodstock quality

3.1.3 Pollution

3.2 Domesticated and SPF/SPR/SPT

broodstock

3.3 Broodstock landing centres and holding techniques

3.4 Broodstock selection and transport from landing/auction centres

3.5 Broodstock utilization

3.6 Broodstock quarantine

3.7 Broodstock health screening

3.8 Broodstock maturation

3.9 Broodstock nutrition

3.10 Broodstock spawning

3.11 Egg hatching

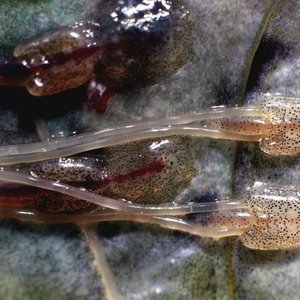

3.12 Nauplius selection

3.13 Egg/nauplius disinfection and washing

3.13.1 Eggs

3.13.2 Nauplii

3.14 Holding and disease testing of nauplii

3.15 Transportation of nauplii

4. POST-SPAWNING PROCEDURES

4.1 Larval-rearing unit preparation

4.2 Larval rearing/health management

4.2.1 Stocking rate

4.2.2 Water exchange protocols

4.2.3 Siphoning of wastes

4.2.4 Aeration

4.2.5 Water quality monitoring

4.2.6 Chemical/antibiotic use

4.2.7 Use of probiotics to replace antibiotics

4.2.8 Responsible use of antibiotics

4.3 Larval nutrition and feed management

4.3.1 Use of live algae

4.3.2 Artemia use

4.3.3 Artificial feeds

4.4 Important larval diseases

4.4.1 Monodon baculovirus (MBV)

4.4.2 White Spot Syndrome Virus (WSSV)

4.4.3 Baculoviral midgut gland necrosis virus (BMNV)

4.4.4 Vibriosis

4.4.5 Larval mycosis

4.4.6 Ciliate infestation

4.4.7 Swollen hind gut (SHG)

4.4.8 Diseases of unknown aetiology

4.5 General assessment of larval condition

4.5.1 Level 1 Health assessment observations

4.5.2 Level 2 Health assessment observations

4.5.3 Level 3 Health assessment techniques

4.6 Quality testing/selection of PL for stocking

4.7 PL harvest and transportation

4.8 Nursery rearing

4.9 Timing of PL stocking

4.10 Use of multiple species in shrimp hatcheries

4.11 Documentation and record keeping

5. REFERENCES

ANNEXES

Annex 1. Persons responsible for compiling this document

Annex 2. Chemicals and treatments used in shrimp aquaculture in India

Annex 3. List of antibiotics and pharmacologically active substances

banned for use in aquaculture in India

Annex 4. Quarantine/maturation tank daily data sheet

Annex 5. Spawning/hatching tank daily data sheet

Annex 6. Larval-rearing tank daily data sheet

Annex 7. Level 1 larval health data sheet

Annex 8. Level 2 larval health data sheet

Annex 9. PL quality testing results sheet

Annex 10. Research and development and extension requirements

Publication

FAO Fisheries Technical Paper. No. 446. Rome, FAO. 2007.101p.

Link