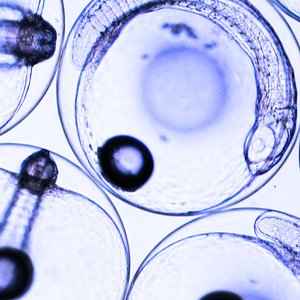

Redd Zone developed a Portable Egg Eyeing Station that provides an oxygen-rich environment for the operator to eye up salmon or trout eggs of any species using up-welling, re-cycled, temperature modulated water.

“Using primarily off-the-shelf components keeps the cost down while maintaining a very stable and easily operated unit,” said Tod Jones, Redd Zone’s president.

Whether deployed to accelerate or decelerate development, the unit can be used for thermal marking of otoliths or even for triploid treatment. If the operator wishes to hatch out and maintain incubation to swim-up fry, a 15-watt UV in-line sterilizer can be added and Best Fry Incubators with media, hatch plate and fry gate.

As the up-welling water is re-cycled, it is re-oxygenated and stripped of any CO2 with an in-line spray bar. The unit also allows for easy prophylactic treatment for fungus using a prescribed dose of rock salt for a prescribed period then easily flushed.

“Our unit is a fourth the cost of other options using vertical trays allowing the operator to have multiple units, each with its own temperature regime. All materials are food-grade quality allowing for easy disinfection. The unit can be connected to the hatchery water source for sustained water level during egg placement or removal or for salt treatment or simply replacing a small amount daily for “sweetening” the system. The unit operates on 115-volt power whether heating or chilling and comes with a three-meter attached power cord,” said Jones.

If requested isolation inserts allow the operator to separate different lots of eggs and/or for adding subsequent eggs without harming eggs from earlier egg takes.

For more information visit reddzone.net.