INVE Aquaculture developed new SEP-Art tools to maintain quality nauplii, reduce losses and ensure safety for workers and the environment and drive efficiency in hatcheries.

Traditionally Artemia nauplii are separated from cysts using a double sieve or a decapsulation method which can cause mortalities in the nauplii, quality issues and is often labor-intensive. Decapsulation is also a chemical exothermic process resulting in the release of waste products and toxic gasses which can be a risk to the environment and operators. During the decapsulation process heat is also produced which can damage Artemia cysts.

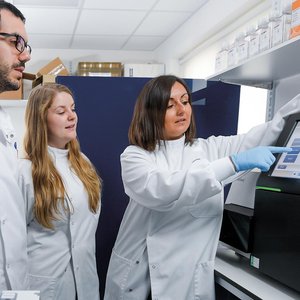

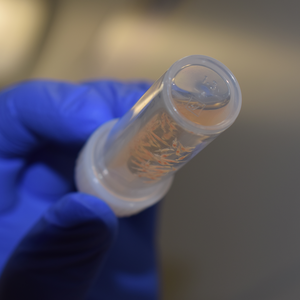

The newly-launched tools are based on the Artemia SEP-Art technology produced by INVE Aquaculture in 2008. The SEP-Art technology consists of cysts covered with iron particles that are attracted to magnets leaving nauplii in the solution. Available in manual, semi-manual and fully automatic, the tools are tailored to all hatchery sizes.

“We have been working on this innovation for over two years and are now very pleased to bring our new tools to the market,” said Geert Rombaut, product portfolio manager. “We always work closely with our customers to understand their needs. Efficiency is an important part of any aquaculture production system and we hope that these tools will support the healthy growth of fish and shrimp and our customer's businesses.”

The three new products, HandyMag, CystTM 2.0 and AutoMag allows all hatcheries, small, medium or large, to produce higher quality nauplii in a standardized and efficient way.