In 2022, Ocean 14 Capital Fund (O14C) invested in clam breeder MITO, which was established through this investment as the consolidation of the separate hatchery and nursery operations of Societá Agricola Ecotapes Italia S.r.L, Ecotapes Zeeland B.V. – the hatchery in the Netherlands – and Delta Futuro Societá Agricola S.r.L. – the nursery in Italy.

Hatchery Feed & Management talked with Francisco Saraiva Gomes, chief investment officer of O14C, to get more insights on how this project can enhance clam production in Europe.

The hatchery

The hatchery site in the Netherlands is situated in a protected area and as such, benefits from excellent environmental conditions and high-water purity, which are perfect for hatching and rearing clam seeds.

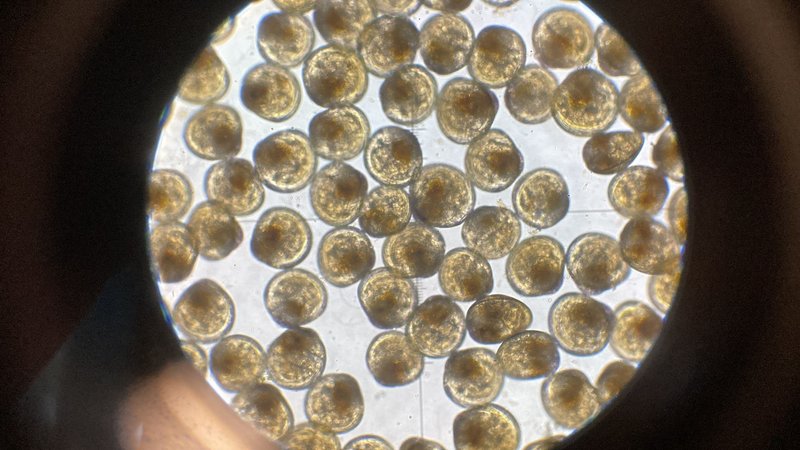

The company is currently focused on producing manila clams (Venerupis philippinarum) with a current production of 300 million seeds at size T0.5 – or 100 million at T3 in the nursery.

“The company operates a standard bivalve hatchery flow-through system, whereby the company pumps water through a filtration system, resulting in highly purified water, and mixes this with algae. This mix is then passed through tanks containing the clams, in a flow mimicking the natural environment,” explained Saraiva Gomes.

The microalgae that are used to feed the clams are T-iso, Chaetoceros, Tetraselmis and Thalassiosira, grown in biosecure photobioreactors.

The company recently entered into a collaborative project with the University of Padua, to create a genetic profiling and breeding program, that began in mid-April.

Credits: MITO

The nursery

The Ecotapes Italia nursery site was already in production in small quantities in 2022 before O14C’s investment. The nursery centers are close to the core Italian market, the largest clam-farming region in Europe.

Mortality for T3+ clam seed at the nursery site is around 60%. Over 2023, the company is aiming to reduce the mortality rate to 55%.

“Survival and production in the hatchery are not only linked to the quality of the water of the site but also to the technical capacity and facilities. In the nursery, the environmental conditions are important, such as water temperature, water quality and nutrient availability. The company controls for these through continuous water quality analysis, lagoon water filtration, bio-secure microalgae production, as well as proprietary know-how that allows for improvements to survivability,” Saraiva Gomes explained.

Future prospects

O14C plans to invest EUR 5 million to scale and grow the business. The company aims to scale up production in two years targeting a production of 2 billion clam seeds. “This will be achieved through capacity increases at both the hatchery and nursery sites,” Saraiva Gomes stated.

A new nursery site, Delta Futuro, is under construction, which will feature a hybrid RAS and tidal flow-through system, and multiple raceways for rearing T1+ seed-size clams.

“The business model, based on a platform bivalve strategy, can be expanded to other bivalve species, as we see a high demand in the market coupled with a lack of supply and overexploitation of wild seed,” Saraiva Gomez concluded.