A new customised dry feed for sea urchins has generated international attention. Scientists at Nofima are now working on reducing production costs and adapting the recipe for large-scale production.

Correct feed is decisive for the farming of sea urchins.

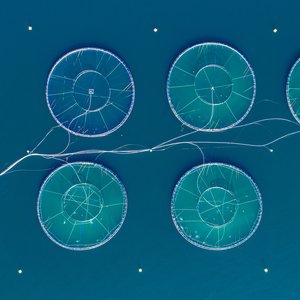

Many of the world's wild sea urchin stocks are over fished and poorer access to sea urchin roe on the market has led to increased interest in farming.

Innovative Norwegian companies are among those that have started farming sea urchins.

Scientists at Nofima (formerly Fiskeriforskning) have developed a dry feed for sea urchins, which has won several feed trials. The good results have led to major demand from sea urchin farmers in a host of countries.

The prototype for the successful feed is now being utilised in the entire Norwegian sea urchin industry, both wild-captured and farmed sea urchins.

"This feed is produced with a thought to nutrition and the sea urchin's biology," says Senior Scientist and feed developer Tor Andreas Samuelsen. "Sea urchins eat well with this feed and the growth of the row is also good."

Feed for large-scale production

However, the successful feed contains very expensive ingredients and has properties that are difficult to produce on a large scale. As a result, farmers can risk insufficient supply and too high a price to achieve profitable production of sea urchins.

The scientists want to do something about this. In the research project, some of the most expensive ingredients are being replaced. In addition, new technology is being utilised to improve both the process and the end result, without reducing the quality of the feed.

"We have made changes to the recipe," says Samuelsen. "We commenced trials in Tromsø last December involving groups of 100 sea urchins receiving different types of feed, which are variants of the recipe."

Senior Scientist Sten Siikavuopio, who has closely followed the sea urchins during the trial, concludes that the trial exceeded all expectations.

"The sea urchins had a good appetite for all of the feeds and the roe had a wonderful size and color," says Siikavuopio, adding: "Sensory tests will determine which feed is best."

Is the roe up to standard?

After the trial, the sea urchins undergo sensory tests. A panel of trained taste judges determine whether the roe quality of the sea urchins that have consumed the new feed variants differs from the sea urchins that received the original super feed.

"The judges taste the roe from the different test groups," says Head of Nofima's Sensory Laboratory in Tromsø, Mats Carlehög. "The method we utilise for judging the roe provides an extremely complex picture of the differences between the various products."

The taste judges are specially trained to be objective and co-ordinated in their assessments. When the roe is served, they judge the properties of the consistency, taste, colour and smell.

The sensory tests, combined with the measurements of the sea urchins' growth and row size, provide the final answer about which feed recipe is best

"The results from the sensory tests are very promising and we have chosen to proceed with one of the feed types," says Samuelsen. "The new recipe makes it both cheaper and easier to produce a good feed."

New equipment speeds up the process

Producing special feed for sea urchins is not a simple task. The feed must be dry, but must be able to sink down to the floor where the sea urchins are. It must have the correct shape and surface and, in addition, be able to last up to a week in water without disolving. This is how long the sea urchin needs to consume the pellet.

In order to determine whether the feed production will function in a factory, Nofima in Bergen is getting new equipment to control the pellet quality relating to structure, strength, stability in water, density, sinking and floating qualities and fat intake.

This equipment makes it even easier to produce high quality feed, not just for shellfish, but also for other marine species such as salmon and cod.

"We have high expectations that we will achieve a feed with the same high quality as the original prototype, but which is suitable for large-scale production," says Samuelsen.

"If everything goes to plan, large-scale production at Felleskjøpet Agri will soon be possible."

Knowledge from this project will also be useful for solving research problems concerning production of feed for king crabs and other types of dry feed for shellfish. This is a collaboration project between Scan Aqua, Felleskjøpet Agri and Nofima, with support from Innovation Norway.

This new equipment at Nofima's feed production facility in Bergen makes it even easier to produce high quality feed.