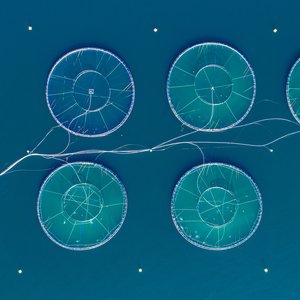

Energy is the second largest cost in a RAS facility after feed. One of the processes in which energy is wasted is when removing carbon dioxide with a degassing unit. There has been a lot of research but few developments on reducing energy used in these units and it is one of the goals of the Norwegian center for research-based innovation, CtrlAQUA.

Currently, CO2 is removed by using gas exchange chambers where water is put into contact with large quantities of air, so CO2 can transfer from the water to the air phase. This CO2-rich air is sent out of the building using electric fans. Here Krüger Kaldnes see great opportunities to improve control over energy. The keywords are pH buffer management and fan automation.

To get to the point where energy is saved, there is a need for a model, a toolbox, to manage carbon dioxide efficiently. “Some of the systems are running in brackish water. In saltwater systems, you challenge the balance in the system, so everything needs to be controlled. To gain this control, we have been working closely with scientists in Nofima and discussing the need for estimating CO2 development based on biomass, feed, pH and other factors,” said Frederic Gaumet, business development manager in aquaculture for Krüger Kaldnes.

Nofima and Krüger Kaldnes are developing the toolbox. The scientists have already done the theoretical work on potential energy savings and carbonate modeling. These models will be validated in practice to make a digital carbonate toolbox to be used in energy management for salmon farmers with RAS. Gaumet said that there is probably room for saving up to 15-20% of the energy used in a RAS facility as a whole, by optimizing the use of energy sources, consumption and by recovering energy from water and air.

To operate and develop these systems further, the industry needs more trained people, as these are big and complex systems. “That’s why we are so eager to use CtrlAQUA as an arena to increase the knowledge of our employees at all levels. We have the great advantage of participating in the discussions with the professionals in the CtrlAQUA consortium and combining the knowledge with the work we do. What makes this consortium very rich is that there is a very good representation of the leading companies in the industry and research institutes that have RAS test facilities,” said Gaumet.

Photo credits: Krüger Kaldnes.